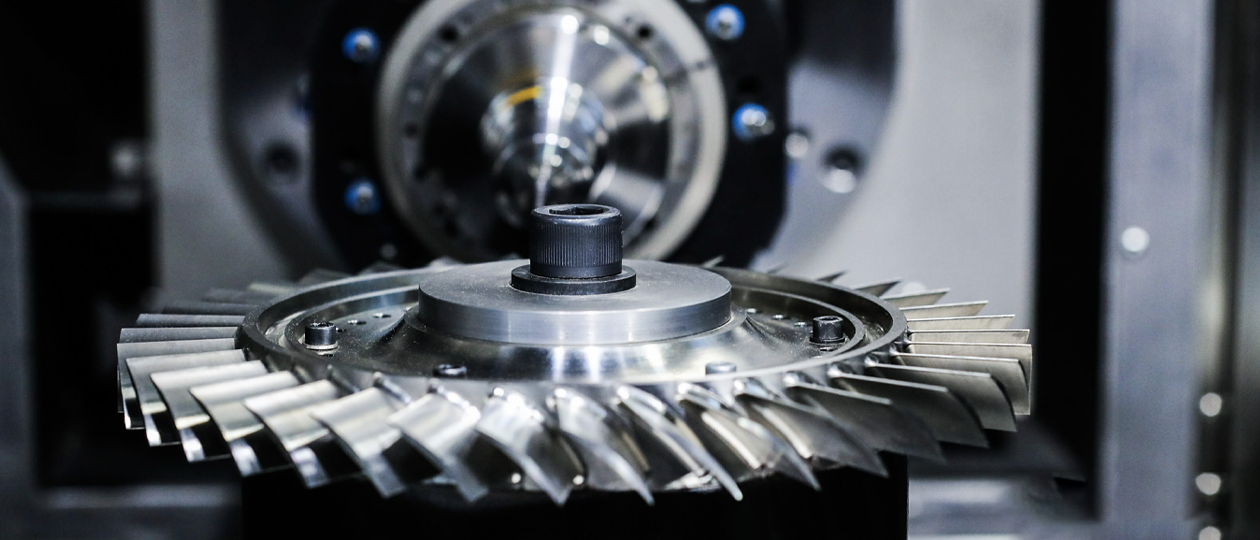

Equipment manufacturing

Genertec actively implements the national strategy of building China into a manufacturing powerhouse, with the manufacturing of high-end numerically controlled machine tools identified as its top-priority core business. In recent years, the group has incorporated seven of the 18 leading machine tool manufacturers in the industry through mergers and acquisitions. These enterprises, with a history of around 70 years, have played a vital role in strengthening China's machine tool industry. Since the founding of the People's Republic of China, they have successively developed the country's first lathe, first drilling machine, first boring machine, and first CNC machine tool—a series of "firsts" that laid the groundwork for China’s industrial modernization.

Today, Genertec has grown into an industry leader with the broadest product portfolio, the widest service coverage, and the most comprehensive technical capabilities in China’s machine tool sector. It is also the largest supplier of high-end core equipment to critical industries and key application areas. Its core machine tool offerings include: precision and ultra-precision CNC machine tools, heavy-duty and super-heavy-duty CNC machines, vertical and horizontal machining centers, multi-axis and five-axis compound machining centers, gear machining machines, electrical discharge machines, measuring tools and gauges, CNC systems and functional components, as well as smart production lines.

Genertec, in partnership with the Tianjin municipal government, has jointly established Genertec Machine Tool , which is responsible for professional division of labor and centralized, unified management of all the group’s machine tool businesses.

The National Machine Tool Production Quality Supervision Testing Center, operated by Genertec, is the first national-level inspection institution in China’s machine tool industry that has been officially authorized to operate as an independent third-party body. Its services cover product testing, certification, diagnostic evaluation, smart manufacturing maturity assessment, standardization research, and common technology development. The center is also recognized as the Industrial Technology Foundation Public Service Platformfor High-end CNC Machine Tools by the Ministry of Industry and Information Technology, the Industrial (Machine Tool) Product Quality Control and Technology Evaluation Laboratory, the National-Level Technology Achievement Testing and Evaluation Institutionby the Ministry of Science and Technology, and a machine tool and robotics testing institution and machinery product certification body by the China Certification and Accreditation Administration.

Genertec has taken the lead in establishing astrategic alliance for technological innovation in the numerically-controlled machine tool industry, joining hands with upstream and downstream enterprises, universities, and research institutions across the industrial chain. The alliance plays a strategic role in ensuring the effective supply of high-end machine tools and enhancing the independence and controllability of the industrial and supply chains.

Looking ahead, Genertec will fully leverage its role as a "national team" in the machine tool industry, further optimize its industrial layout and product mix, improve its science and technology innovation system, and advance the upgrading of industrial foundations and the modernization of industrial chains. The group is committed to achieving a high level of self-reliance in science and technology, and to building a world-class high-end machine tool equipment enterprise with core technologies and strong global competitiveness—thus providing solid support for China’s new development paradigm and the national strategy of building a manufacturing powerhouse.

Business map